Modern fire extinguishers have evolved beyond simple water-based systems to include sophisticated gaseous clean agents and specialized powders designed for combustible metals. These eight distinct types of fire extinguishers—Water, Water Mist, Foam, ABC Dry Chemical, Carbon Dioxide, Wet Chemical, Dry Powder, and Clean Agents—each utilize unique chemical properties to disrupt the fire triangle (heat, fuel, and oxygen). Whether the goal is to prevent thermal runaway in lithium-ion batteries or to protect sensitive electronic circuitry without leaving a corrosive residue, selecting the right fire extinguisher requires a precise understanding of the specific risks present in your environment.

| Extinguisher Type | Label Color | Best For (Classes) | Avoid Using On |

| Water | Bright Red | Class A (Wood, Paper) | Electrical, Liquid, Grease |

| Foam (AFFF) | Cream | Class A & B (Liquids) | Electrical Fires |

| ABC Dry Powder | Blue | Class A, B, C & Electrical | Enclosed spaces (Inhalation risk) |

| Carbon Dioxide (CO2) | Black | Class B & Electrical | Kitchen/Grease fires |

| Wet Chemical | Yellow | Class K (Cooking Oils) | Flammable Liquids/Gases |

| Water Mist | White | Class A & Electrical | Class D (Metals) |

| Dry Powder (L2/M28) | Blue | Class D (Metals/Lithium) | All other fire classes |

| Clean Agent | Green/White | Electronics/Data Centers | Deep-seated Class A fires |

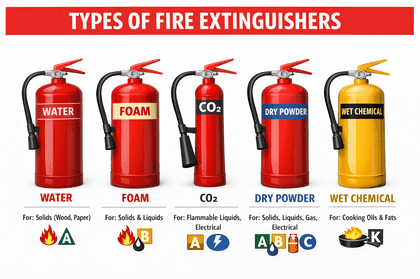

1. Water Fire Extinguishers (Class A)

Water fire extinguishers are used for A class fires involving solid materials including wood, paper, textiles, and plastics.

Working Principle: Water fire extinguishers work by cooling burning materials to below the ignition temperature of fire, absorbing heat and breaking the fire triangle, effectively preventing re-ignition.

Used in: offices, schools, warehouses, and residential buildings

Not used in: electrical, flammable liquid, or gas fires.

2. Foam Fire Extinguishers (Class A & B)

Foam Fire Extinguishers are effective in A class and B class fires and are used for flammable liquids like petrol and diesel, plus other solvents.

Working Principle: Foam forms a stable blanket over the burning surface and cuts off oxygen, simultaneously cooling the fuel to prevent re-ignition.

Used in: fuel storage areas, garages, workshops, and commercial buildings.

Not used in: gas fires or in the presence of live electrical instruments.

3. Dry Chemical Fire Extinguishers (ABC Type)

Dry Chemical fire extinguishers handle class A, B, and C fires including flammable burning gases.

Working Principle: The powder used interrupts the chemical chain reaction of the fire and creates a barrier by separating fuel and oxygen to suppress flames. Utilizing monoammonium phosphate, this agent coats the fuel and smothers the fire. It is a multipurpose agent and the most common type found in commercial buildings.

Used in: industrial sites, outdoor areas, vehicles and construction zones.

Limitations: reduced visibility and residue after discharge

4. Carbon Dioxide (CO2) Fire Extinguishers (Class B & Electrical)

CO2 fire extinguishers are very suitable for use on electrical fires and fires of Class B flammable liquids.

Working Principle: Carbon dioxide is a so- called inert gas which does not support combustion. It displaces the oxygen around the fire to such a level that it hardly supports combustion anymore. The gas also has a limited cooling effect as it expands.

Applications: server rooms, electrical panels, laboratories, offices

Advantages: no residue, non, conductive

5. Wet Chemical Fire Extinguishers (Class K / F)

Wet chemical fire extinguishers are aimed at Class K (or Class F) fires, i.e. fires of cooking oils and fats.

Working Principle: When wet chemical and hot oil meet, a reaction called saponification takes place, which results in the formation of a soap-like layer that seals the surface, cools the fire and prevents firing again.

Applications: commercial kitchens, restaurants, hotels

Essential for: deep fat fryers

6. Clean Agent Fire Extinguishers

Clean agent fire extinguishers are gas based (e.g. FM 200 or Novec 1230) and are ideal for places where sensitive electronic equipment is present.

Working Principle: Clean agents work by both absorbing heat and breaking the chemical reaction of the fire. They do this without changing the oxygen concentration to levels that are unsafe for humans. The fires are put out very fast and without leaving any residue behind.

Applications: Data centers, control rooms, medical facilities

Advantages: non-corrosive, eco-friendly, electronics-safe

7. Water Mist Fire Extinguishers

Water mist fire extinguishers represent a state of the art and earth-friendly alternative mainly for usage in Class A, limited Class B, and electrical fires.

Working Principle: Water mist fire extinguishers work by local removal of oxygen and rapid cooling of the fire through ultra-fine water droplets at the same time, ultra-fine water droplets being non-conductive make them safe for electrical equipment.

Used in: Hospitals, museums, offices, public buildings

Advantages: No chemicals, very little water damage

8. Dry Powder Fire Extinguishers (Metal Fires)

Dry powder fire extinguishers are used for fires involving combustible metals such as magnesium, sodium, lithium, and aluminum powder. Class D extinguishers often use a low-velocity applicator to ensure the powder gently smothers the burning metal without scattering it. As EV and e-bike usage increases, ensuring you have an L2 powder or a specialized AVD (Lithium-Ex) extinguisher is critical for battery safety.

Working Principle:

Specialized powders smother the fire and absorb heat, forming a crust that isolates the metal from oxygen and stops the reaction.

Used in: metal processing plants, laboratories, manufacturing units

Critical: must match the extinguisher to the specific metal